We have a proven reputation for delivering the highest quality products, with broad and varied sector experience, meeting complex engineering challenges.

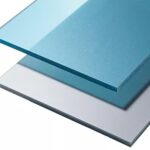

Durapoll AR

Abrasion Resistant Polycarbonate

Domer Durapoll AR

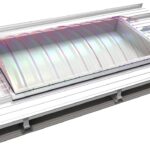

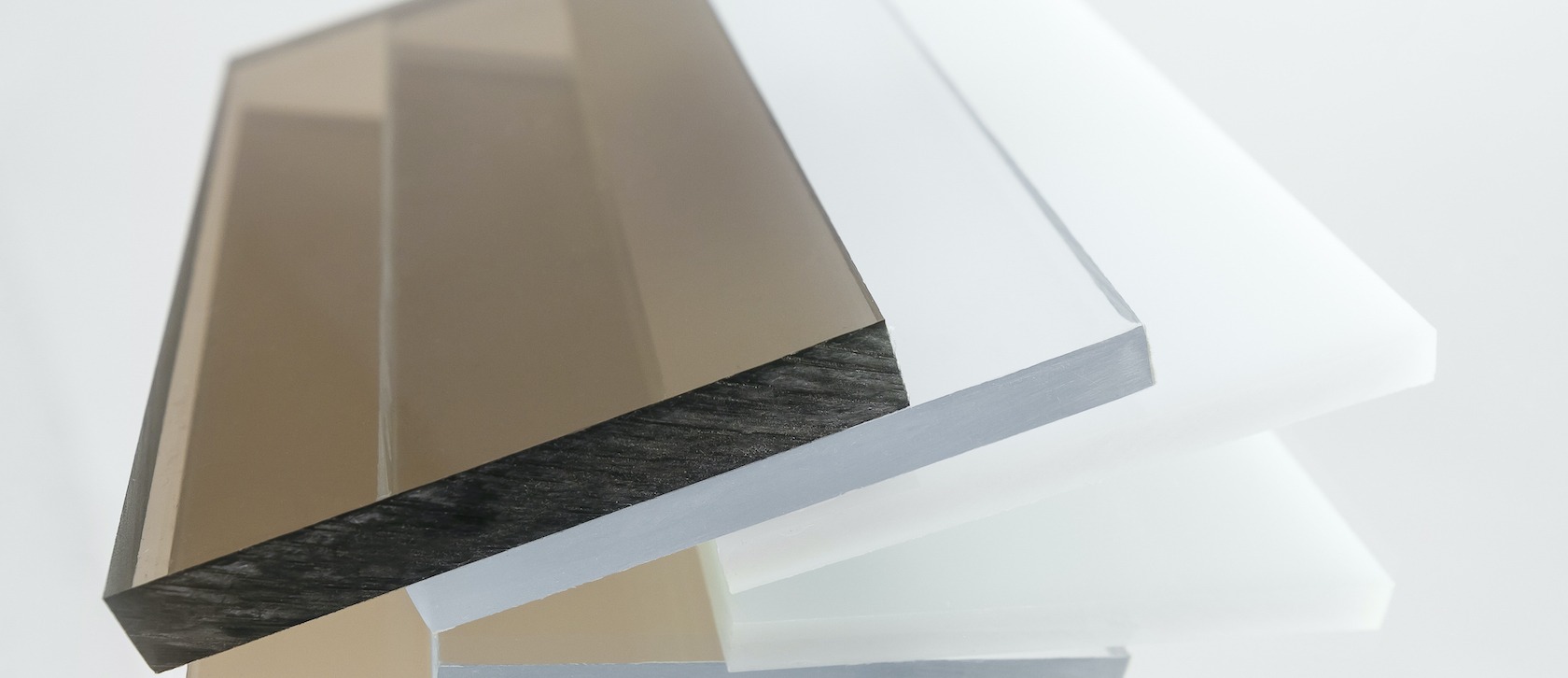

polycarbonate sheet is one or both sides hard-coated polycarbonate offering excellent performance and resistance against scratches, marks, graffiti, vandalism, and physical attack.

Domer Durapoll AR sheets can be co-extruded with a UV protection layer blocking all harmful UV rays and preserving their light transmission and properties over the years.

Applications:

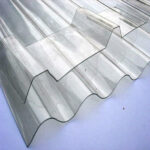

- Safety and security glazing

- Anti-vandal glazing

- Prison windows

- Sound barriers

- Protective visors and helmets

- Machine guards

- Bus stops and booths

Abrasion Resistant Polycarbonate

sheet provides 250-300 times more impact resistance than glass at only half the weight, making it suitable for construction glazing, preventing a violent break-in. Besides, polycarbonate abrasion-resistant sheets’ outstanding strength and security make them ideal for museum showcase, protective shield, door, and bullet-proof glass.

The unique Durapoll AR coating on the polycarbonate sheet surface guarantees its durability and resistance against various chemicals ranging from corrosive elements and solvents to cleaning agents. Graffiti spray can be removed easily, and the sheet are ideal for industrial environments where volatile chemicals are present.

Product Benefits:

- Abrasion-resistant on one or both sides

- Lightweight and easy to handle

- High chemical resistant

- High natural light transmission up to 91%

- Excellent acoustical insulation

- Excellent weather and UV resistant

| Product Name | Description |

|---|---|

| Domer Durapoll AR | Abrasion Resistant Solid polycarbonate sheets |

| Thickness | Length | Width |

|---|---|---|

| 0.8 - 3.0mm | No Limit | ≤ 2100mm |

| 3.0 - 20mm | No Limit | ≤ 2450mm |

*customized sizes are available subject to minimum order quantity

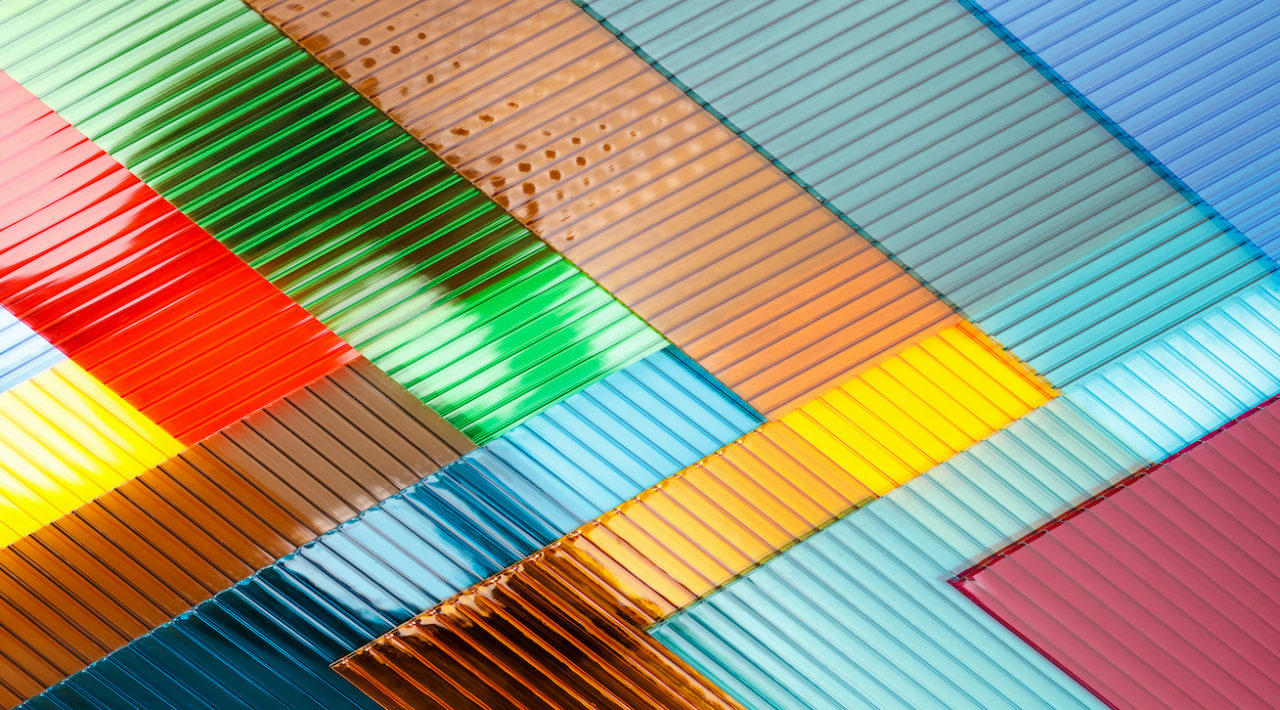

| Type | Color |

|---|---|

| Opaque | white, navy blue, sky blue, dark green, mint green, yellow, light grey, dark grey, red, brick red, orange |

| Translucent | transparent clear, opal, bluewish, greenish, yellowish, greyish, reddish, orange |

| Finishing | |

|---|---|

| Solar Control | Colors can be customized subject to minimum order quantity |

| Diffused | Colors can be customized subject to minimum order quantity |

| Dotted | Colors can be customized subject to minimum order quantity |

*Colors and Finishes can be customized subject to minimum order quantity

| Property | Test Method | Conditions | Units | Value |

|---|---|---|---|---|

| Physical | ||||

| Densitiy | D-792 | g/cm3 | 1.2 | |

| Water Absorption | D-570 | 24 hr. @ 23°C | % | 0.15 |

| Mechanical | ||||

| Tensile Strength at break | D-638 | 10 mm/min | Mpa | 65 |

| Elongation at break | D-638 | 10 mm/min | % | >80 |

| Tensile Modulus of Elasticity | D-638 | 1 mm/min | Mpa | 2300 |

| Flexural Modulus | D-790 | 1.3 mm/min | Mpa | 2350 |

| Rockwell Hardness | D-785 | R scale | 125 |

| Property | Test Method | Conditions | Units | Value |

|---|---|---|---|---|

| Thermal | ||||

| Long Term Service Temperature | °C | |||

| Short Term Service Temperature | °C | |||

| Coefficient of Linear Expansion | D-696 | mm/m°C | 0.065 | |

| Thermal Conductivity | C-177 | W/mK | 0.21 |

| Property | Test Method | Conditions | Units | Value |

|---|---|---|---|---|

| Optical | ||||

| Haze | D-1003 | Clear Sheet | % | <0.5 |

| Light Transmission | D-1003 | Clear Sheet | % | 90% |

| Refractive Index | D-542 | Clear Sheet | 1586 | |

| Yellowness Index | D-1925 | Clear Sheet | <1 |

browse what can be done using our products

Our diverse portfolio represents decades of experience backed by a passion for quality, outstanding client service, and the latest industry technologies.

Community Noise Control

Area

Wall

Suggested product

Durapoll NC

Material

Polycarbonate

Type

Solid Noise Control

Glazed Wall

AREA

Wall

SUGGESTED PRODUCTS

ContiWall, ContiRoof, Durapoll PS, Multipoll, Vivid PS,

MATERIAL

Polycarbonate, GRP

TYPE

Multiwall, Solid, Corrugated

Railway Noise Control

Area

Wall

Suggested product

Durapoll NC

Material

Polycarbonate

Type

Solid Noise Control

quality products. inspired design.

unparalleled experience. exemplary service.

Common Questions & Answers

Is polycarbonate chemical resistant?

Polycarbonate is resistant to most common chemicals as mineral acids, many organic acids, oxidizing and reducing agents, neutral and acid salt solutions, many greases, waxes and oils, saturated, aliphatic, and cycloaliphatic hydrocarbons and alcohols, (with the exception of methyl alcohol).

Please contact Domer for more information.

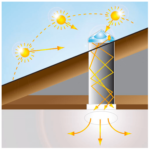

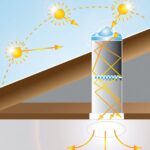

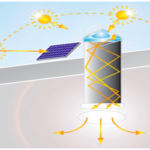

Does polycarbonate block the UV radiation?

Domer’s polycarbonate sheets can be co-extruded with one side or both sides UV protection layer to block UV radiation while bringing natural light into the building. This enables the panels to last for many many years without fading or discoloring. It is recommended to install the sheets with the marked UV protective layer facing outwards the sun.

What is the difference between polycarbonate solid sheets and multiwall?

Polycarbonate solid sheet is a compact material offering excellent mechanical properties while multiwall sheets have a minimum of two layers having an air space between them providing excellent thermal insulation while maintaining much lower weight due to its hollow structure.

Can solid polycarbonate sheets be used in the same manner as glass?

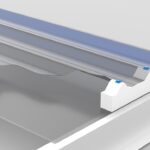

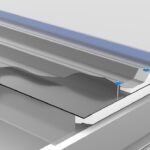

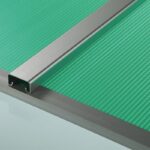

Polycarbonate sheets can be used very effectively to replace glass, and be installed similarly with glazing aluminum profiles and EPDM gaskets. Space must be reserved for the thermal expansion of PC sheets.

Please contact Domer for more information.

Goal

We strive to build a better community and make a difference in the world